You build it. LINE-X protects it.

LINE-X® Protective Coatings have virtually unlimited potential applications for any business serious about protecting and prolonging the life of its products. Companies around the world requiring corrosion-, abrasion-, and impact-resistant coatings trust our high-performance polyurethane/polyurea elastomer coatings. For over 20 years, LINE-X has provided our manufacturing partners with enhanced surface coatings aimed at improving operational efficiencies, increasing product durability, and boosting end-user satisfaction.

LINE-X Protective Coatings are environmentally friendly, contain no volatile organic compounds (VOCs), and provide solutions for businesses that are subject to industry-specific regulatory compliances and severe service environments.

Superior Customer/Tech Service

Product & Application Expertise

Creative Solutions Specifically for Your Manufacturing Process

CORROSION PROTECTION

LINE-X industrial protective coatings are designed to create an impenetrable barrier between valuable equipment and nature’s harshest elements, such as high humidity, saltwater, or extreme temperature changes.

COMPREHENSIVE ENVIRONMENTAL PROTECTION

LINE-X industrial coatings are ideal for secondary containment applications, providing an additional layer of environmental protection wherever petroleum products or chemicals are stored.

UNMATCHED ABRASION AND IMPACT PROTECTION

Laboratory tests demonstrate excellent levels of abrasion and impact resistance under just about any severe-use condition. LINE-X outperformed all other leading materials, including carbon and stainless steel.

CUSTOM COLORS & UV STABILIZATION AVAILABLE

LINE-X is available in a wide variety of custom colors and UV stabilization to provide a truly unique, lasting performance coating.

PERMANENT BOND

Because LINE-X Protective Coatings form permanent bonds at the molecular level, they have excellent adhesion to a wide variety of surfaces. Whether applied to metal, fiberglass, concrete, plastic, or wood, LINE-X can absorb impact and resist damage by remaining both flexible and strong, without losing adhesion. That makes LINE-X perfect for protecting and increasing the lifecycle of your product line.

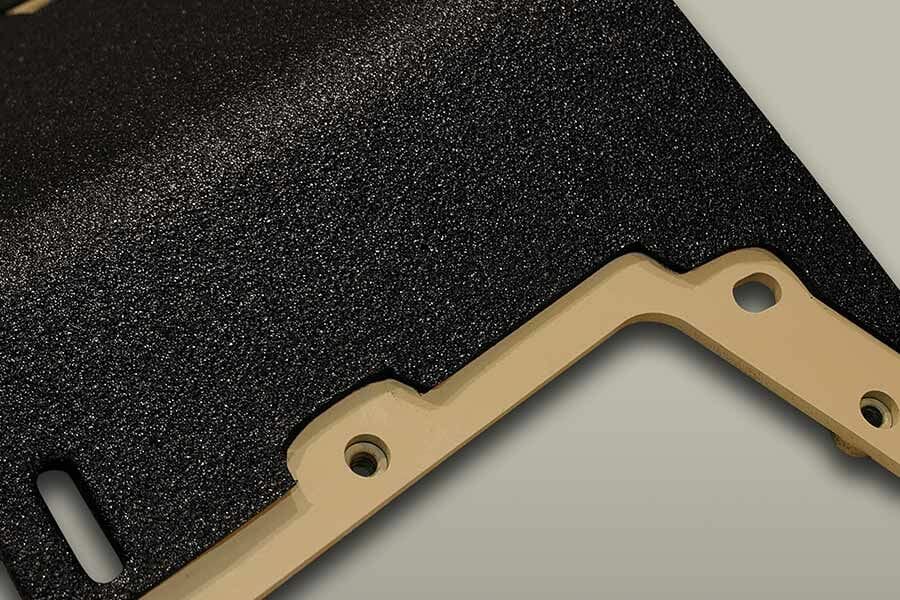

SKID- AND SLIP-RESISTANT

Like the ridges in a fingerprint, LINE-X coatings are textured for grip. The texture on the surface of the coating provides traction for step pads, ramps, cargo areas, and equipment.

Established industries where LINE-X is currently part of the manufacturing process

Automotive & Utility Vehicles

Specialty and utility truck bodies, accessory manufacturers, fire apparatus, emergency response vehicles, RVs, UTVs, and more.

FIRE TRUCKS

LINE-X fire truck coatings help protect those who protect us, providing first responders added durability, toughness, slip resistance and protection on their equipment.

Marine

Aluminum boat manufacturers, boat trailers, personal watercraft, and more.

Recreational Vehicles

RV and toy hauler manufacturers, UTV/RTV, side X side and off-road vehicles.

Transportation

Trailer manufacturers, railroad equipment infrastructure, and storage containers.

Secutiy & Defense

Ballistic plates and personal body armor.

With over 20 formulas available, LINE-X can be used to protect, reinforce, and enhance. Our most popular industrial products are utilized by manufacturers around the world.

XS-100

XS-100 is a user-friendly polyurethane and polyurea formulation that has earned industry respect for its durable, long-lasting, high-performance qualities protecting truck beds across the globe. Perfect for protecting your most valuable assets from abrasion, corrosion, and impact, XS-100 was designed with the highest chemical equilibrium in its polymerization network — softness vs. hardness, toughness vs. longevity, durability vs. impact, etc.

XS-152

Any company looking for protection against abrasion and impact, but also needing flame retardant properties should look to XS-152. It has been tested for flame spread and smoke density per ASTM E-84. This product is ideal for the military and mining industries.

XS-350

XS-350 is a pure polyurea coating with high-performance physical properties perfect for applications beset with chemical damage or extreme impact and abrasion. XS-350 is very insensitive to moisture and can be seen widely used in the wastewater industry.

XS-650

XS-650 is an aliphatic polyurea that provides outstanding UV stability with excellent color and gloss retention. It is a versatile coating with virtually limitless possibilities. XS-650 can be applied in a thick-film application and offers exceptional adhesion properties for high-abrasion and high-use environments without the need of a UV-stable topcoat. With strong physical properties, it is an ideal coating for marine applications, theme parks, trolling motors, RV roofs, automotive applications, and products requiring extreme durability and UV protection.